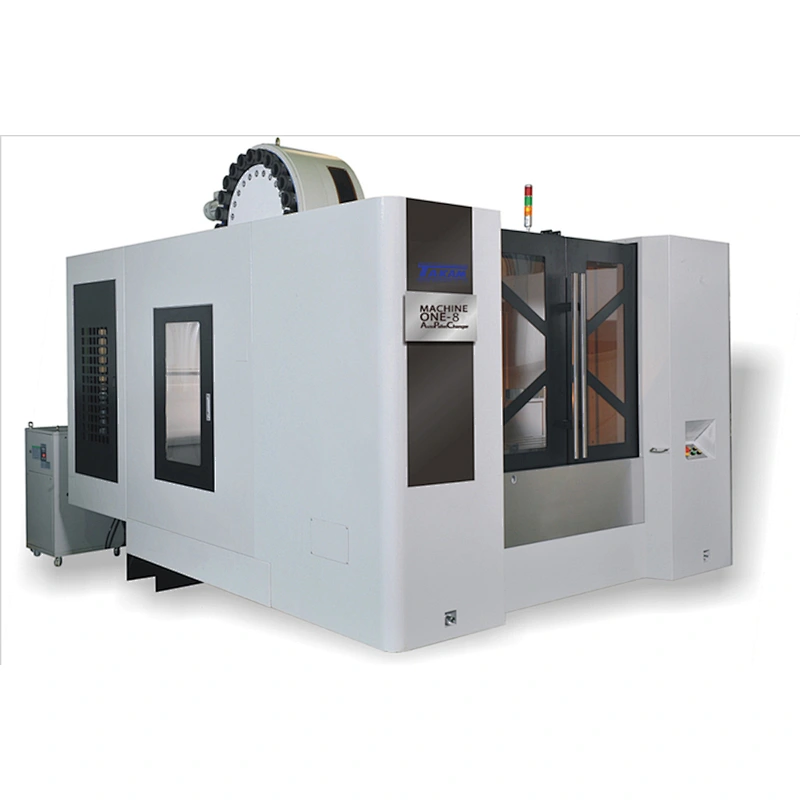

M-ONE 8 APC Vertical Machine With High Speed Pallet Changer

High-Speed CNC Vertical Auto Pallet Change Machining Center With global demand increasing, limited factory floor space and shortage of labor force.Many companies have been looking for solutions that can help with these increasing problems.Takam M-ONE APC Series (Auto Pallet Change) vertical machine center is the best solution for this type of needs. With the M-ONE APC Series gets 25% to 60% increase in productivity compare to only one machine working. By not stopping the machine after every machining cycle, this machine can work non-stop while the work-piece is getting changed.

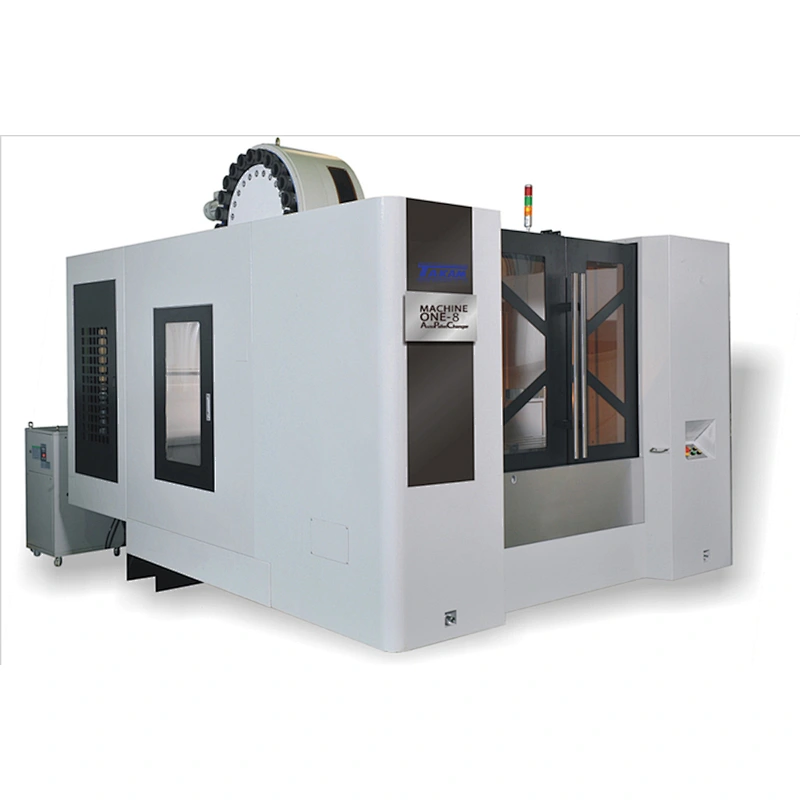

Body Structure

The M-ONE APC is desgined with the perfect platform, no matter what the project is the soundnessof the structure is determined by the sturdiness of the foundation. The same principle applies to our APC machining centers. The machine structure is also made from high grade cast iron. It is reinforced with heavy ribs to resist vibration and damping. Also, the widestance design allows maximum loading for the machine.

Table Change Time

When every second counts, a fast table change is very important. The M-ONE APC (Auto Pallet Change) fast table change is what we do. Our table change time from the moment of lift off with complete 180 degree turn only takes less than 7 seconds decreasing production time.

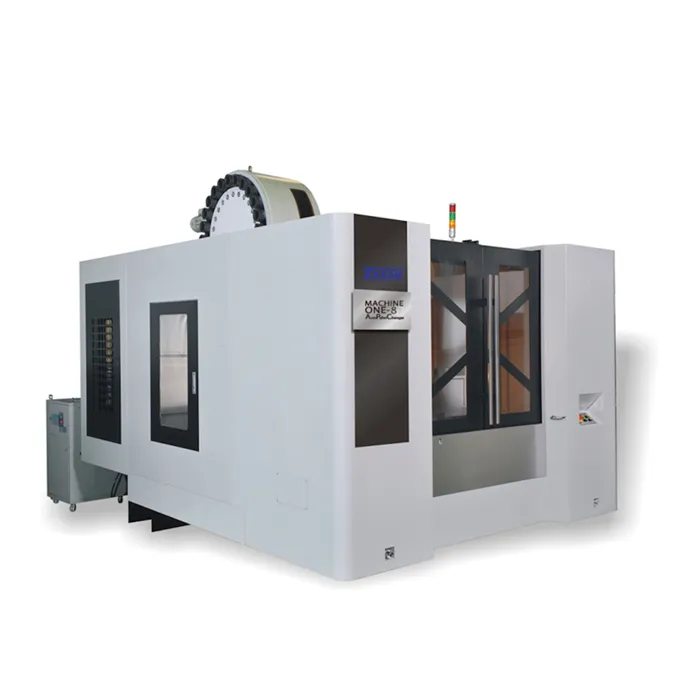

Operating Panel

The M-ONE APC Series operating panel was designed with the comfort of the operator in mind. Since this machine was designed to operate for long working hours, the operating panel can be rotated left to right and up and down to the maximum comfort of the operator.

M-ONE 8 APC Machine Data Specifications

Subject | Unit | Size |

Work table size | MM | 850 x 500 |

Machining area | MM | 850 x 500 |

Number of pallet | Piece | 2 |

T Slot | MM | 100×18×5 |

Max weight on work table | KG | 300 x 2 |

X/Y/Z Axis travel | MM | 850/500/600 |

Spindle nose to work table surface | MM | 150-750 |

Spindle taper | | BT40 |

Spindle RPM | RPM | 10000 |

Spindle delivery type | | Belt |

Spindle motor | KW/HP | 7.5 |

Axis motor(Mitsubishi) | KW | 2.0/2.0/3.5 |

Axis motor(Fanuc) | KW | 3/3/3 |

Cutting feed rate(X/Y/Z Axis) | MM/min | 1-12000 |

Rapid feed rate(X/Y/Z Axis) | M/min | 36/36/36 |

Position accuracy | MM | ±0.005 |

Repeatability | MM | ±0.003 |

Air requirement | KG/cm2 | 6 |

Cooling pump | HP | 3/4 |

Voltage requirement | KVA | 17.5 |

Machine Weight | KG | 6500 |

Exterior size(L×W×H) | MM | 2810 x 5570 x 3300 |