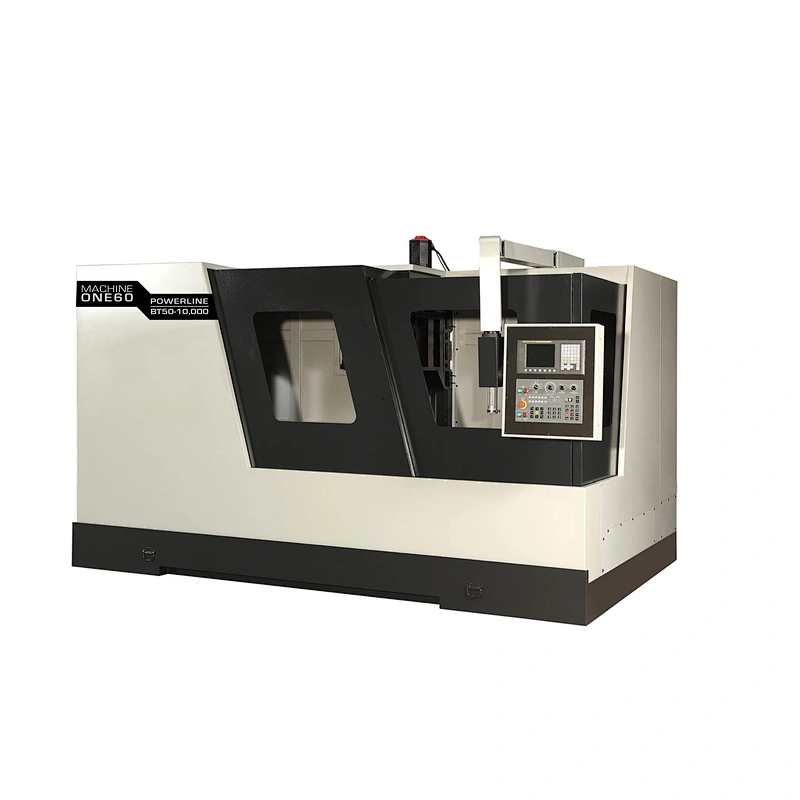

ALL NEW DESIGN

TAKAM Machinery uses the strongest, most durable and fastest machine.

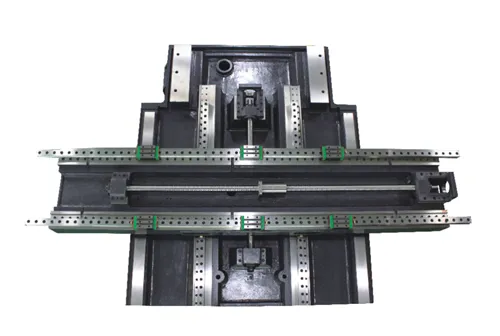

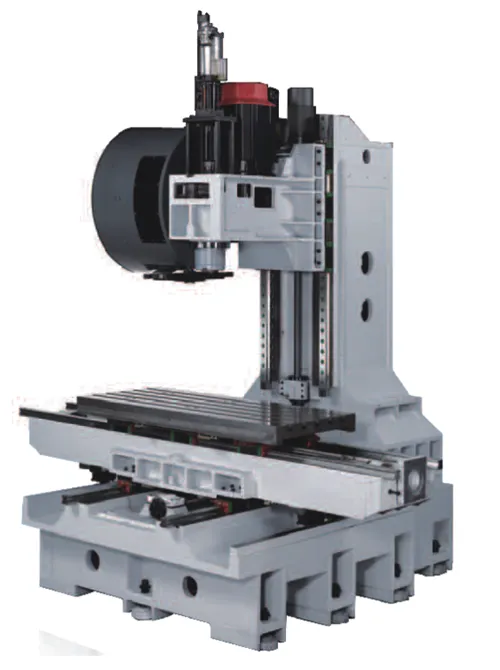

It is hard to believe there is a better designed vertical machine out there. For the M-ONE 60 vertical machine in the Z-Axis we go against the norm and use 6 high precision sliding blocks to increase the rigidity, also to ensure the when the machine is undergoing heavy duty machining.

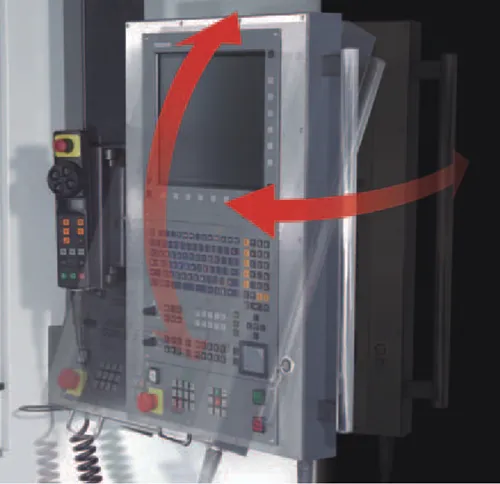

M-ONE Series Control Panel

The M-ONE 60 machine control is designed with the operator in mind.The control panel design gives the operator maximum comfort since the operator can adjust the control panel to their specific needs.

Since the control panel is adjustable with maximum comfort the operator can be able to have long operating hour without the feel of tiredness.

Strong Powerful Base

The M-ONE 60 Vertical machine center is designed with heavy duty cutting for its main purpose.

That is why for the M-ONE 60 vertical machine center's base has four guideways in its Y-Axis, as you can see in the photo above besides the two linear guideways, there is also two additional box way guides as support to withhold the heavy pressure when the machine is going through the heavy cutting process.

FASTER, STRONGER ----- THIS IS THE M-ONE SERIES

With the consideration of speed and productivity in mind, we especially analyzed and made sure our machine structure is different compared to other manufacturers. We found a way to decrease the heavyweight but increase the rigidity and durability of the machine. From the testing of the machine to every precision part that is used on this machine is all carefully selected.

Rapid travel | Every axis | C3 High grade |

36m/min | 7 bearings | import ball screws |

model

subject | M-ONE60 |

| Work table size (mm) | 1,700*700 |

| Machining area (mm) | 1,600*700 |

| X/Y/Z Axis travel (mm) | 1,600*700*620 |

| Spindle motor (kw/hp) | 15/18.5 |

| Axis motor(Mitsubishi)(kw) | 3/3/3 |

| Axis motor(Fanuc)(kw) | 3/3/3 |

| Cutting feed rate(X/Y/Z Axis)(mm/min) | 1-10,000 |

| Rapid feed rate(X/Y/Z Axis)(m/min) | 36/36/24 |

| (X/Y/Z Axis) Linear guideway | |

| Position accuracy (mm)± | ±0.005 |

| Repeatability (mm)± | ±0.003 |